Color fastness of upholstery fabrics

Rubbing fastness

In addition to light fastness (topic in edition no. 5), rubbing fastness also is an essential quality criterion for the evaluation of upholstery fabrics. The two terms rubbing fastness and light fastness belong to the topic color fastness. For a better understanding: Light fastness is the resistance of an upholstery fabric against the exposure to artificial or natural light. Rubbing fastness is the resistance of the fabric’s color against rubbing off and staining other materials.

RUBBING FASTNESS:

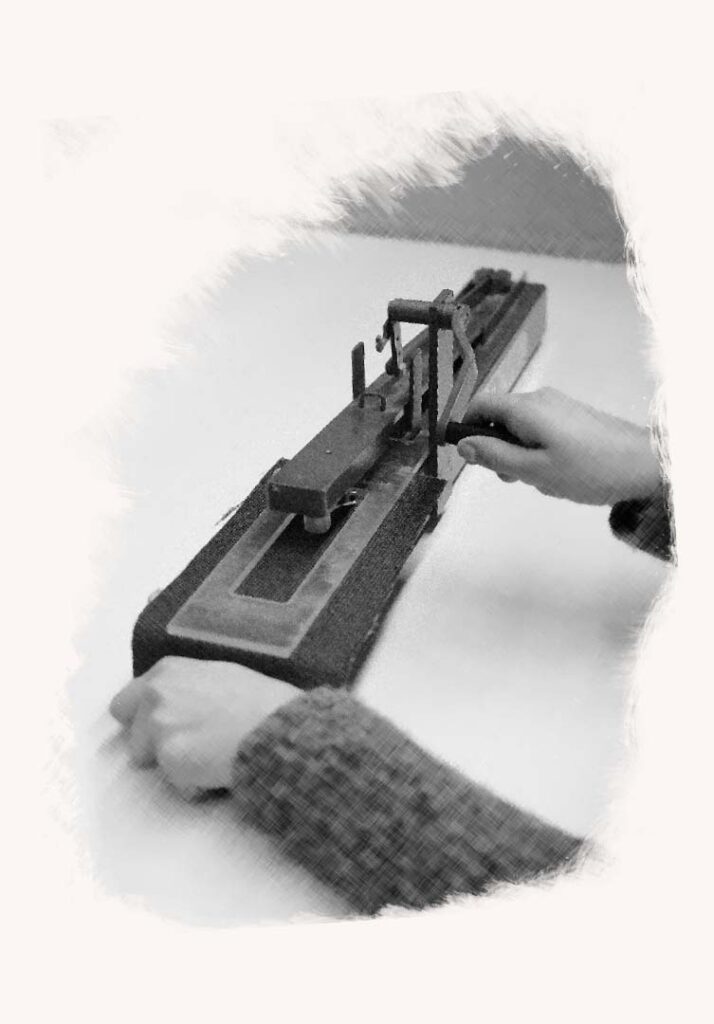

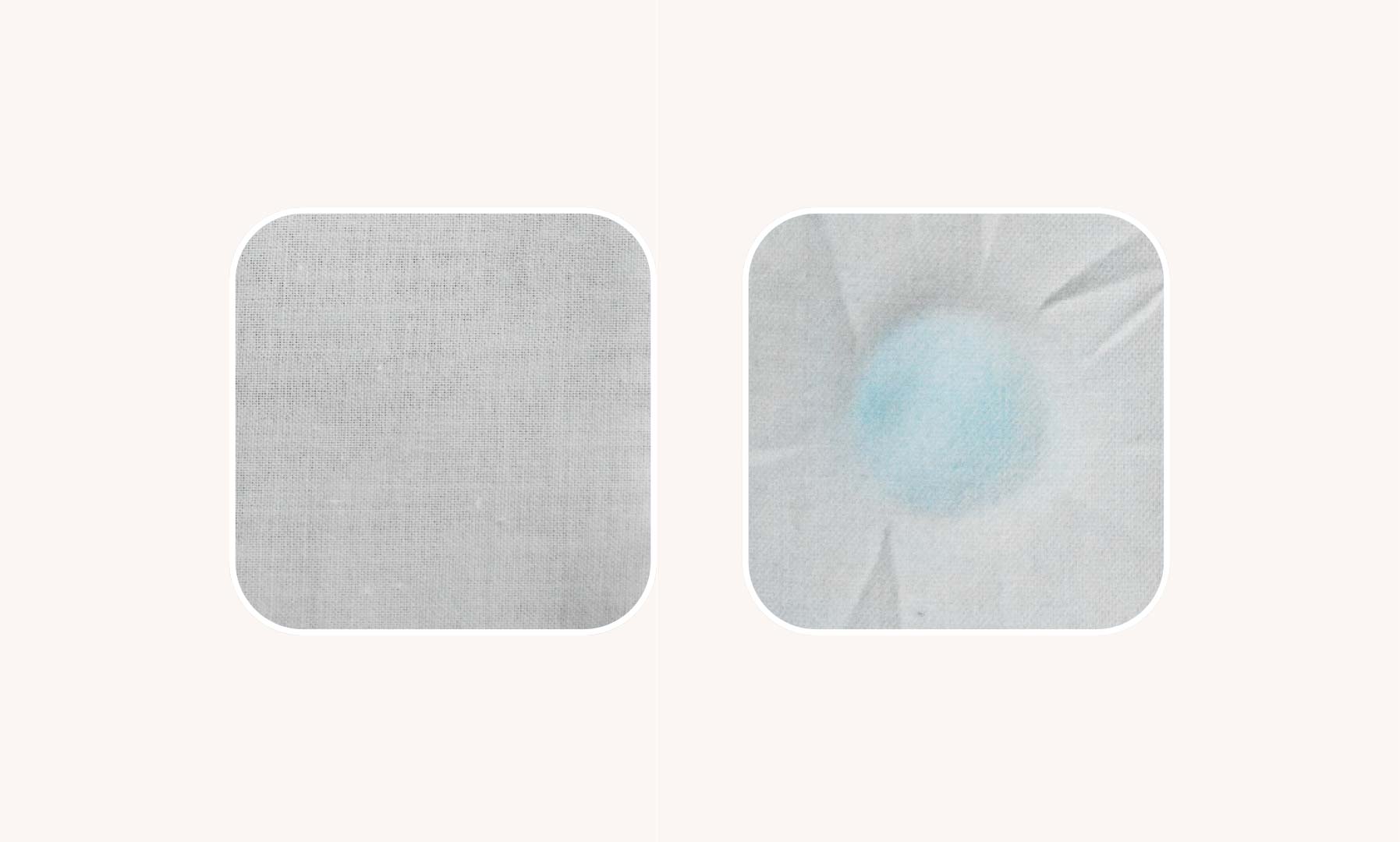

When testing the rubbing fastness by means of the crockmeter, one differentiates between dry and wet rubbing fastness. In doing so, the fabric sample is rubbed against a white cotton fabric using a defined pressure. This is done by reciprocating. The rubbing fastness is also tested in wet condition because dyed textiles usually lose more color while wet. Due to the mechanical abrasion, part of the dye of the upholstery fabric rubs off on the white cotton fabric and colors it. The intensity of the coloring is evaluated using a five-tier scale (so-called grey scale) as seen in the picture below. Level 1 (or grade 1) is the lowest value, level 5 is the best value. At level 5, the cotton fabric hasn’t changed.

According to the regulations of the DGM (Deutsche Gütegemeinschaft Möbel e.V.), grade 4 is required for upholstery fabrics in dry condition, in wet condition it’s grade 3. For particularly dark and brilliant colors containing natural fibers, grade 2/3 is required. The values of Rohleder Q2 fabrics are in the upper range. That means, rubbing fastness in dry condition is evaluated with grade 4/5-5, in wet condition it’s grade 4-4/5.

Test with a blue fabric (natural fiber). Left: Close-up of the white cotton fabric before testing. Right: The same sample after testing in wet condition with visible color abrasion (grade 2 – 2/3).